Robinson utilizes flexible manufacturing to ramp up production

Robinson offers a flexible approach to manufacturing when fulfilling customer requirements. Flexibility with facility layout, equipment layout, and modular tooling in manufacturing are utilized to support our customer needs. Aligning manufacturing resources to unique customer applications has proven to be positive for Robinson’s growth.

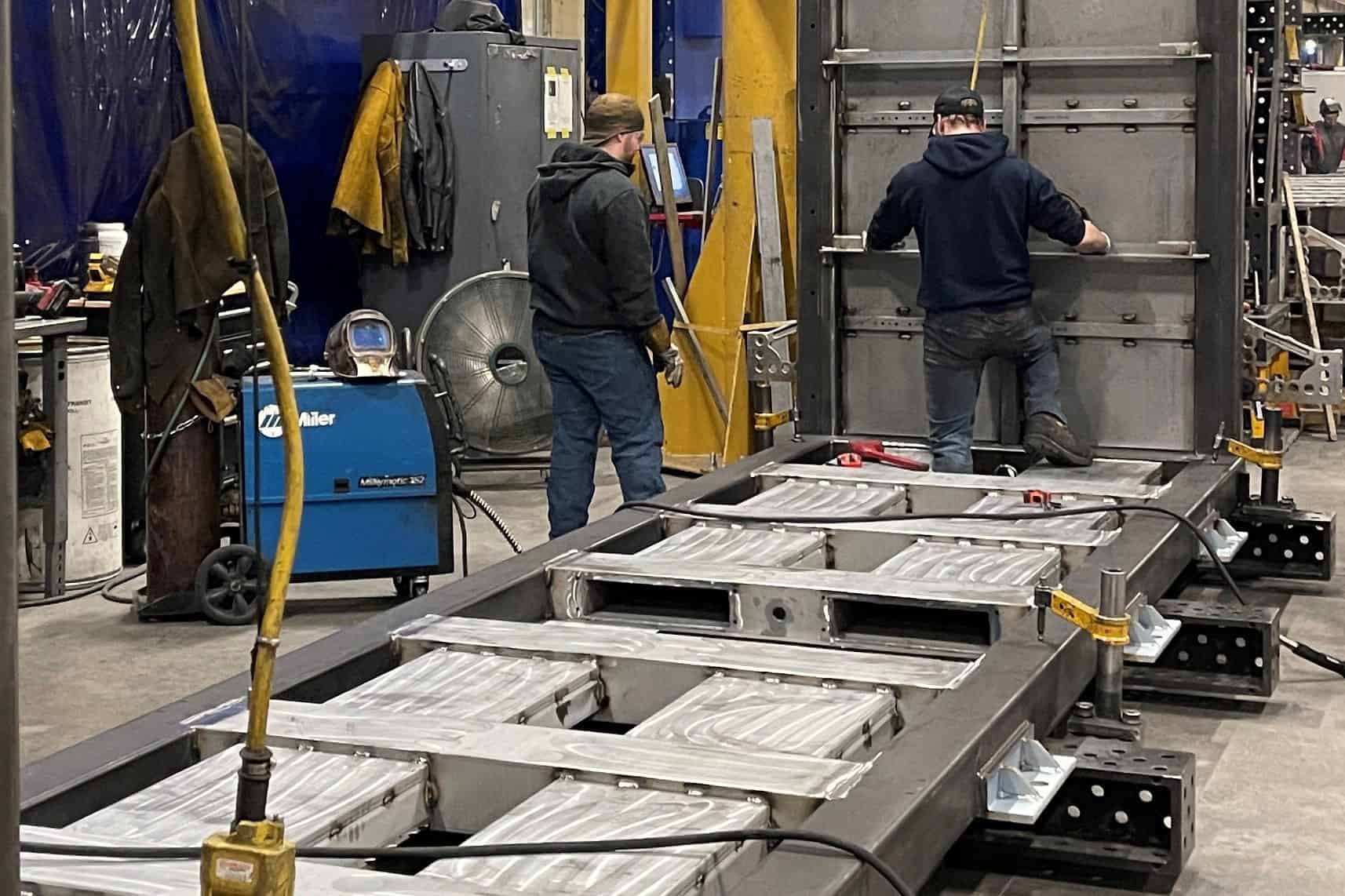

Modular tooling in manufacturing allows for a nimble approach to project development and production ramp-up. Having the ability to use standard components to erect a unique fixture for customer applications reduces lead times while maintaining tight tolerances.

“Our team can formulate a plan using modular tooling in manufacturing that supports the early phases of product development through production ramp up“ explains Jeff Kroening, Director of Sales for Robinson. “We are able to provide tight tolerance qualification units and consistently hold those tolerances during high volume production.”

Robust systems support modular tooling in manufacturing

We use modular tooling in manufacturing in a variety of production scenarios, including the fulfillment of integrated energy storage systems. Our project design specialists leverage sophisticated analysis to take customer designs from prototype to production.

This robust system ensures repeatability in production processes and consistency of output. Our flexible manufacturing model eliminates the variabilities that come with less robust processes and helps you maintain a competitive edge in your market.

“Modular tooling in manufacturing supports flexible manufacturing and allows us to minimize costs and maintain ISO-driven processes regardless of production volume,” Kroening says. “We utilize modular tooling in manufacturing with our preferred production partners, to achieve efficiency gains and maintain high levels of quality for the end product.”

About Robinson, Inc.

Robinson, Inc., is a single-source metal solutions provider based in De Pere, Wisconsin. Robinson offers design, manufacturing and production fabrication for a wide range of industries. The company employs nearly 600 people at three Wisconsin locations comprising 525,000 square feet of manufacturing space.

For more information about Robinson’s capabilities or to request a quote, please call (920) 494-7411, or visit https://robinsoninc.com.

View the original post on modular tooling in manufacturing here.