Carbon Fiber Bridge Sleeves to Withstand the Stresses of High-Speed Presses

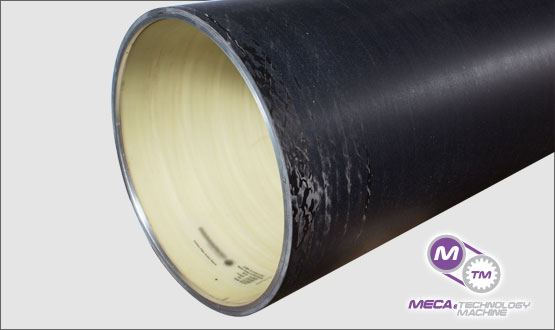

GREEN BAY, Wis. – When it comes to printing, there is always a question of what sleeves and bridges to use to achieve maximum production. Carbon fiber bridge sleeves from MECA & Technology Machine offer an option away from the old standard. In comparison to standard composite bridge sleeves, the carbon fiber bridge sleeves are stronger and have more vibration absorption properties, which allows them to operate at higher speeds.

GREEN BAY, Wis. – When it comes to printing, there is always a question of what sleeves and bridges to use to achieve maximum production. Carbon fiber bridge sleeves from MECA & Technology Machine offer an option away from the old standard. In comparison to standard composite bridge sleeves, the carbon fiber bridge sleeves are stronger and have more vibration absorption properties, which allows them to operate at higher speeds.

“Some customers think that carbon fiber won’t be as durable,” says Mick Karchinksi, Vice President of Sales at MECA & Technology Machine. “Designed for maximum stiffness, MECA’s carbon fiber bridge sleeves withstand the process, even at high speeds. They provide optimal performance for your printing.”

Carbon fiber bridge sleeves from MECA & Technology Machine are adaptable for use with any style base mandrel. Not only is carbon fiber strong enough to withstand the printing process, they absorb vibration and are as rigid as steel cylinders, allowing them to operate at faster speeds. They are available in lengths from 12 to 120 inches with diameters from 3 to 16 inches. “Save time and money and reduce waste with MECA’s carbon fiber bridge sleeves,” finishes Karchinski.

MECA & Technology Machine employs approximately 50 people at its Green Bay, Wisconsin facility. For more information about the company’s carbon fiber bridge sleeves or carbon fiber mandrels, call Mick Karchinski at (920) 336-7382.

View the original post at Blog | MECA & Technology Machine