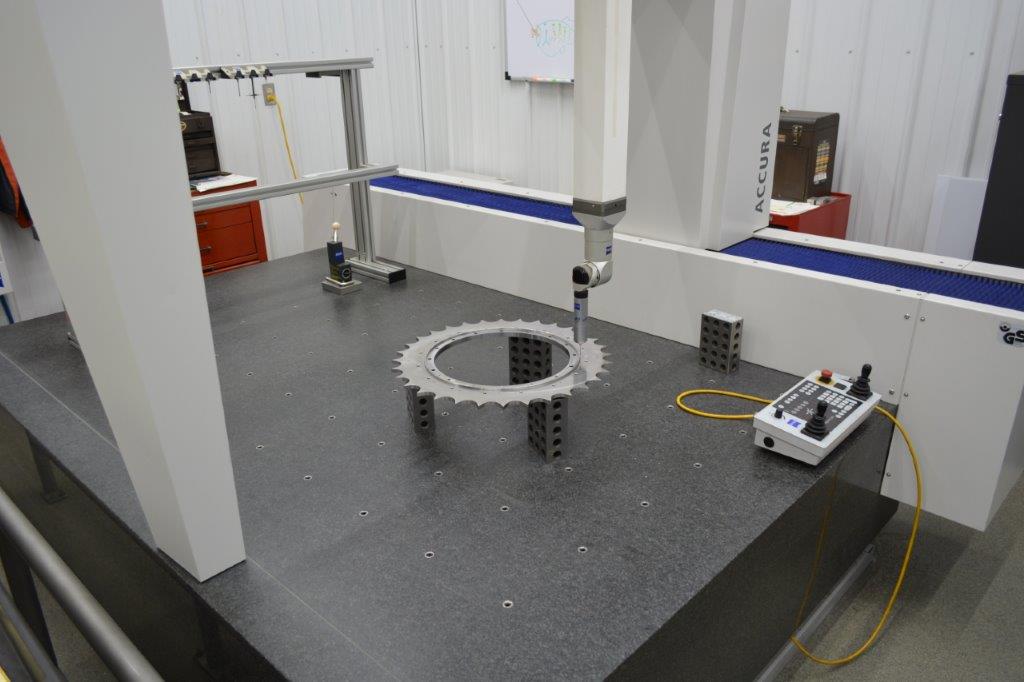

Coordinate Measuring Machine Verifies Tight Tolerance Metal Parts

CMM inspection capabilities give Robinson Fabrication and Machine, a division of Robinson Metal, Inc., the ability to provide customers with quality verification for parts produced in its De Pere, Wisconsin, facility. Coordinate measuring machines enable metal fabricators to authenticate the accuracy of machining operations.

CMM inspection capabilities give Robinson Fabrication and Machine, a division of Robinson Metal, Inc., the ability to provide customers with quality verification for parts produced in its De Pere, Wisconsin, facility. Coordinate measuring machines enable metal fabricators to authenticate the accuracy of machining operations.

Robinson Fab and Machine customers receive documented verification that parts have been manufactured properly and to specification, eliminating downtime and generating valuable peace of mind.

“CMM inspection in Wisconsin typically is limited to larger shops such as ours because of the investment involved,” said Jamie Tilkens, Robinson Fab and Machine division manager. “It gives us the advantage of ensuring our quality is at the highest standards, and our customers appreciate that extra step of confirmation.”

Robinson Fab and Machine uses CMM inspection for very tight tolerance parts. Details such as hole location and size, and other geometric specifications are analyzed in three dimensions. The machine’s touch probe can measure parts as large as 1,200 millimeters on the x-axis, 1,800 mm on the y-axis, and 1,000 mm on the z-axis.

Technicians input the part’s drawing into the CMM’s software, from which the computer can verify accuracy against the target specifications. CMM inspection is possible for virtually every feature specified in the plans.

“The system also can produce documentation of manufacturing accuracy for customer records,” Tilkens said. “This is useful in tracking the long-term maintenance and performance history for the part, removing any doubt as to whether it was manufactured correctly should any issues arise.”

Robinson Fab and Machine provides a variety of metal forming services for customers in industries as varied as pharmaceutical, food and dairy, water treatment, oil and gas, architectural design and others.

About Robinson Metal, Inc.

Robinson Metal operates out of a custom-designed, 185,000-square-foot modern facility that also features a segregated stainless steel fabrication area. The company is a single-source metal fabrication supplier, employing approximately 300 people at its facilities in De Pere, Wisconsin. Its four divisions include: Fab and Machine; Pipe and Vessel; Robinson Custom Enclosures; and Robinson Heating and Cooling.

For more information about Robinson Fab and Machine’s precision machining capabilities, please call (920) 494-7411, or visit http://robinsonmetal.com/.

View original post on CMM inspection here.