Thorvie Offers Quality Equipment and Business Opportunities

Have you wondered about the legitimacy of all of the saw sharpening equipment for sale in the marketplace? It seems every day someone makes the claim that theirs is the best. But as you do your research, you’ll quickly discover there’s no comparison to Thorvie International.

“We’ve been engineering and manufacturing our equipment since 1977 and in all those years we’ve only gotten better at what we have to offer,” says Ken Frea, president of Thorvie International. “Not only is our equipment superior, but our comprehensive business program offers entrepreneurs a low-risk, maximum profit opportunity. No one else in the industry does that.”

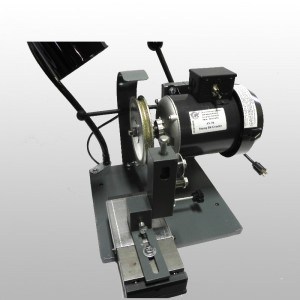

Thorvie’s AV-40 professional grinder sharpens saw blades, face, top and side grinds, and sharpens many different cutting tools. It maintains a wheel RPM of 3450, which is essential when grinding carbide tooling. Its bearing assembly has four bearings, while many other grinders typically only have three. This allows the saw blade and tool holder to give precision grinding performance.

Thorvie’s AV-40 professional grinder sharpens saw blades, face, top and side grinds, and sharpens many different cutting tools. It maintains a wheel RPM of 3450, which is essential when grinding carbide tooling. Its bearing assembly has four bearings, while many other grinders typically only have three. This allows the saw blade and tool holder to give precision grinding performance.

The AV-40 saw and tool sharpening system does not stop with just sharpening saw blades. With the AV-40 sharpening machine’s versatile design, you can sharpen jointer, planer and chipper knives which no other saw blade sharpening machine will offer. The AV-40 knife grinding fixture will sharpen knives to the same height without having to purchase a separate sharpening system. Simply remove the AV-40 saddle assembly and mount the knife-grinding fixture to the table base within seconds. With the knife-grinding fixture you can straight grind carbide knives or put the correct hollow grind in steel knives to the same quality as an expensive knife grinder for a fraction of the cost.

The AV-40 saw and tool sharpening system is designed with one thing in mind, our customers. It allows you to sharpen a wide range of tools with one system to maximize your profits. Compared to other systems, the AV-40 grinder is far less expensive, and when you buy directly from Thorvie, you’ll save 40 percent or more.

For more information on saw sharpening equipment for sale, call Thorvie International at 866-497-0572.

Rick’s Tip

The router bit fixture for the AV-40 sharpening system will sharpen steel and carbide router bits. When sharpening router bits, I like to set the motor quadrant on zero which allows me to see where I am sharpening better. Some people like to set the motor quadrant on 90 degrees and either sharpening method will give you the same sharpening results. There are two main points to making sure you have sharpened the router bit properly, keeping the flutes balanced and creating a new sharp cutting edge. The proper way to balance a router bit is to sharpen each flute with the same amount of grinding passes. If you take 4 grinding passes on one flute, sharpen the other flute with 4 grinding passes also. On steel bits, you will know you have created a new sharp edge when a slight burr is created on the cutting edge. Using a small wet stone will remove the burr easily. On carbide router bits it can be harder to tell if the cutting edge has been sharpened properly as carbide does not create a burr. I always felt pen the area I am sharpening to make sure I am aligned correctly and also to see when the entire surface has been sharpened. To test a carbide router bit you can use a soft piece of plastic. Set the router bit cutting edge on the soft plastic block and by hand rotate the bit will light pressure. The cutting edge will lift a small shaving from the plastic block with ease. If you have to use a lot of pressure, the bit will require more sharpening.

View the original post at Thorvie International