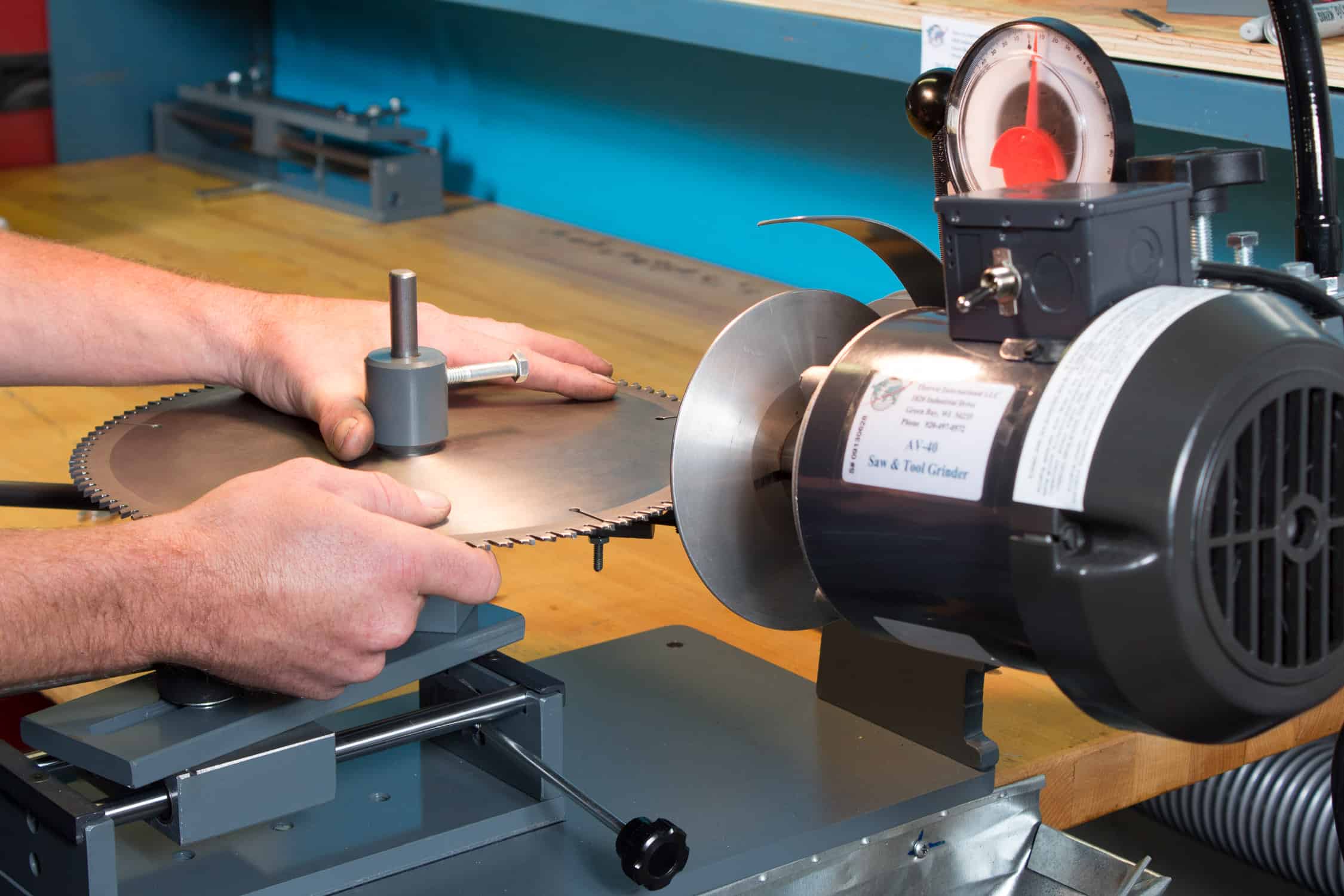

The AV-40 Is A Cut Above The Rest

Think if you’ve seen one tool sharpening machine you’ve seen them all? Think again. The AV-40 professional grinder is the industry leader.

Think if you’ve seen one tool sharpening machine you’ve seen them all? Think again. The AV-40 professional grinder is the industry leader.

Made by Thorvie International, the AV-40 tool sharpening machine does it all. It sharpens saw blades, panel and profile cutters, anti-kickback router bits and shaper cutters without motor interference, something few saw blade grinders can offer. The machine’s motor maintains a wheel RPM of 3450, which is essential when grinding carbide tooling. In addition, its bearing assembly has four bearings, while many other grinders typically only have three.

“This allows the AV-40 saw blade and tool holder to give you precision grinding performance as the saddle bearing assembly is solid with no play whatsoever,” explains Thorvie International President Ken Frea.

Another advantage for aspiring entrepreneurs? Compared to other systems, the AV-40 grinder is far less expensive. Plus, when buying manufacturer direct from Thorvie International you’ll save 40% or more!

For more information on the AV-40 tool sharpening machine, call 866-497-0572

Rick’s tip

The knife grinding fixture for the Thorvie AV-40 saw and tool sharpening machine will allow you to sharpen jointer, planer and chipper knives. When sharpening steel jointer and planer knives, set the knife fixture at an angle on the Thorvie AV-40 table base which will then sharpen a hollow grind in the steel knives. By hollow grinding steel knives, you will get a much sharper cutting edge than if you straight grind the knives.

After you have ground the knife and created a new burr along the cutting surface, remove the burr with a wet stone or with the polishing wheel provided in the Thorvie AV-40 saw and tool sharpening package. When sharpening carbide jointer and planer knives, you want to straight grind the knives, so set the knife fixture straight on the Thorvie AV-40 table base. If you were to hollow grind a set of carbide jointer or planer knives, you will weaken the cutting edge.

Carbide is not designed to have a sharp knife-like edge. With carbide knives, no burr will be created. The edge of carbide rolls off and the best way to make sure you have a new cutting edge is to use a felt pen on the surface you are grinding and make sure all of the marks are removed. If you are unsure if a set of knives are steel or carbide, run a file across the knife. If it is really hard and you can’t cut into the knife with a file, then it is carbide.

View the original post at