MECA Specializes in Designing Bridge Sleeves to Outfit Your Printing Press

MECA’s carbon fiber bridge sleeves have become a primary asset in the ever-expanding search for speed and quality in the flexographic printing industry. MECA has taken consistency to a higher level as an industry leader in the design and production of carbon fiber bridge sleeves.

MECA’s carbon fiber bridge sleeves have become a primary asset in the ever-expanding search for speed and quality in the flexographic printing industry. MECA has taken consistency to a higher level as an industry leader in the design and production of carbon fiber bridge sleeves.

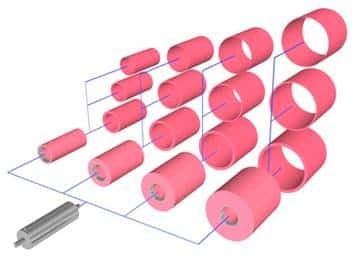

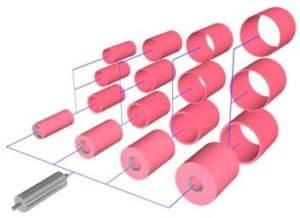

Bridge sleeves (or adaptors) support printing sleeves in building a larger print diameter to achieve desired printing repeats. The idea is to “bridge” your base mandrel to allow for lighter and more cost effective plate sleeves. Bridge sleeves are commonly used in flexographic presses, although they can be used in other applications. MECA’s light-weight, carbon fiber bridge sleeves perform exceptionally well at high speeds without forfeiting stiffness at the point of impression. The decreased weight of carbon fiber offers the added benefit of generating less stress on drive motors to achieve the desired results.

“Today’s high-speed presses demand vibration absorption properties possible from modern carbon fiber bridge sleeves that are superior to traditional materials,” said Jim Berceau, general manager at MECA. “Our engineering and production teams are constantly refining techniques to provide our customers with the highest-quality bridge sleeves.”

MECA’s sales and engineering team will work with your pre-press department, maintenance managers and purchasing to ensure that we design your bridge sleeve to meet your presses needs and functions. MECA can also help you size your bridge sleeve to maximize the ROI on your bridge sleeve.

“We like to think of MECA’s carbon fiber bridge sleeves as an investment in your press,” says Timothy L. Olson, technical sales manager. “MECA can look at your press’s repeat range and choose the right size bridge sleeve to significantly lower the cost of printing sleeves and maximize your ROI on the bridges.”

About MECA

MECA is an innovative engineering provider and manufacturer of precision rolls, tight tolerance machined components, gears, composite plate and bridge sleeves, aluminum and carbon fiber anilox sleeves, and mechanically engraved cylinders for the industrial printing, coating and web converting industries. The company employs more than 60 people at its facility in Green Bay, Wisconsin (USA).

For more information about MECA’s design and manufacturing capabilities email our sales team [email protected] or Timothy L. Olson at [email protected]. You may also call our offices at 920-336-7382, or visit https://www.mecagb.com/.

View original post on carbon fiber bridge sleeves here.