Specially formulated construction material provides greater stability

Specially formulated construction material provides greater stability

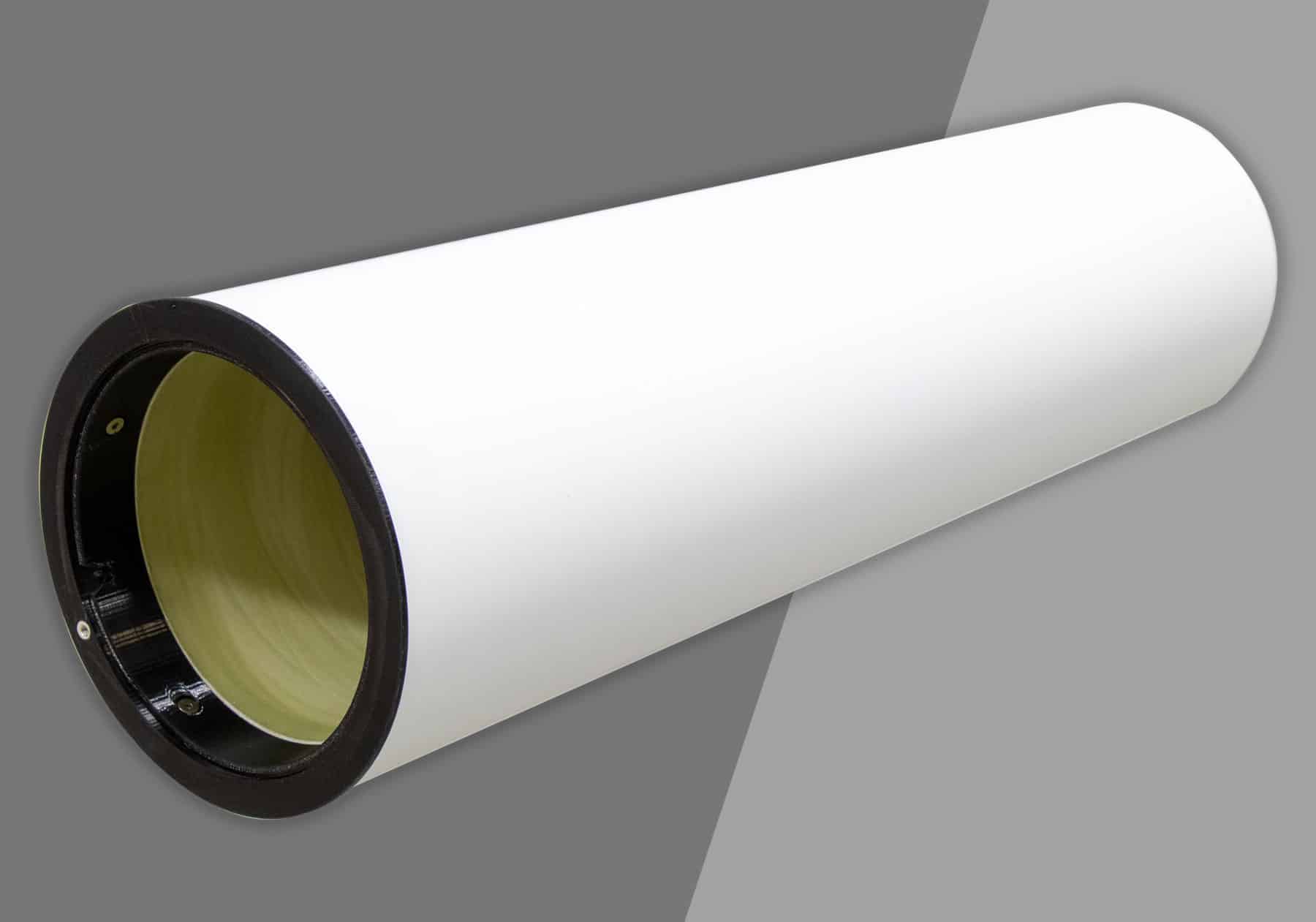

High-quality flexographic printing for packaging relies on print sleeves that retain their dimensional integrity regardless of environmental variables. MECA has designed print sleeves and anilox sleeves to do just that, creating the ideal pairing for industry-leading flexographic printing for packaging.

MECA specially formulates its print sleeves for optimal performance in specific processes. The vinyl ester resin base is a different material than used by many of our competitors. It is very stable, and does not shrink or expand under hot or cold conditions. Tolerances also hold true after cleaning with harsh chemicals for long-term quality in flexographic printing for packaging.

In addition to benefitting from the premium quality of MECA’s print sleeves, our customers appreciate the rapid and dependable lead times that are a consistent focus of our business model. Typical lead times are just three weeks, with rush orders delivered in two weeks or less.

MECA’s products are American-made in Green Bay, Wisconsin, meaning shipping is faster and cheaper than with competitors who import from overseas manufacturers. Delays at ports of entry, customs delays and today’s wildly fluctuating shipping costs make domestic purchases a choice which will benefit your operations.

Flexographic printing for packaging just got easier

MECA offers several key optional features for flexographic print sleeves, including pull rings as an assist for an operator-aided grabbing point for faster removal and replacement of anilox sleeves. An added benefit of pull rings is they can be color coded for easy sleeve identification purposes, as most patterns that are laser-engraved into anilox sleeves are too fine to identify easily without the assistance of magnification.

In addition to the color-coded pull rings, we also offer the more common aluminum pull rings. Whether the pull rings are color-coded (so operators can quickly identify specific cell patterns) or traditional aluminum, they are a great feature to minimize changeover times and the potential for mistakes.

MECA’s commitment to helping customers optimize efficiencies and safety in flexographic printing for packaging complements other premium product attributes, including nip point safety that is a characteristic of high-performance vacuum rolls.

For more information about MECA’s full line of rolls and sleeves for flexographic printing for packaging, please call (920) 336-7382, or visit https://www.mecagb.com/.

About MECA

MECA is a premier manufacturer of precision rolls for the printing and web handling industries. MECA specializes in flexographic print sleeves, heat transfer rolls, carry rolls, mandrels, coating rolls and vacuum rolls. As part of the Precision Roll Solutions family, MECA helps the world’s leading manufacturers leverage texture and other process variables to make their products more effective and enhance their impact in the marketplace.

View the original post on flexographic printing for packaging here.