Enhanced CNC Machining Capabilities Enhance Speed and Accuracy

Enhanced CNC Machining Capabilities Enhance Speed and Accuracy

Consistent investments in industry-leading tools and CNC machines are only part of the commitment to excellence for Titletown Manufacturing, a leader in parts machining, and steel and aluminum fabrication in Green Bay. Today’s metal shop environment requires attention to regular software upgrades that push productivity to higher levels.

Titletown Manufacturing has dedicated significant resources toward software upgrades in the office as well as the shop floor that generate process efficiencies and consistently high-quality products.

“It is important that we give our team the best tools available in both the business and production aspects of our process,” says Titletown Manufacturing co-owner Chris Fuss. “Software upgrades are not cheap, but we definitely feel we get a return on our investment in the quality of work we produce for our customers.”

Mastercam 2018 and MazaCAM Software Upgrades Lead the Way

Titletown Manufacturing’s shop floor features a range of CNC machines that operate on Mastercam and MazaCAM programming technology. Software upgrades to both programs enable enhanced functionality while minimizing the potential for human error.

“The result is faster programming and interaction with our machine tools that allow us to produce parts consistently to customer specifications,” says Titletown Manufacturing co-owner Dan Hilliard. “This enhances quality while minimizing turnaround times for tight-tolerance parts, especially those with complex geometries.”

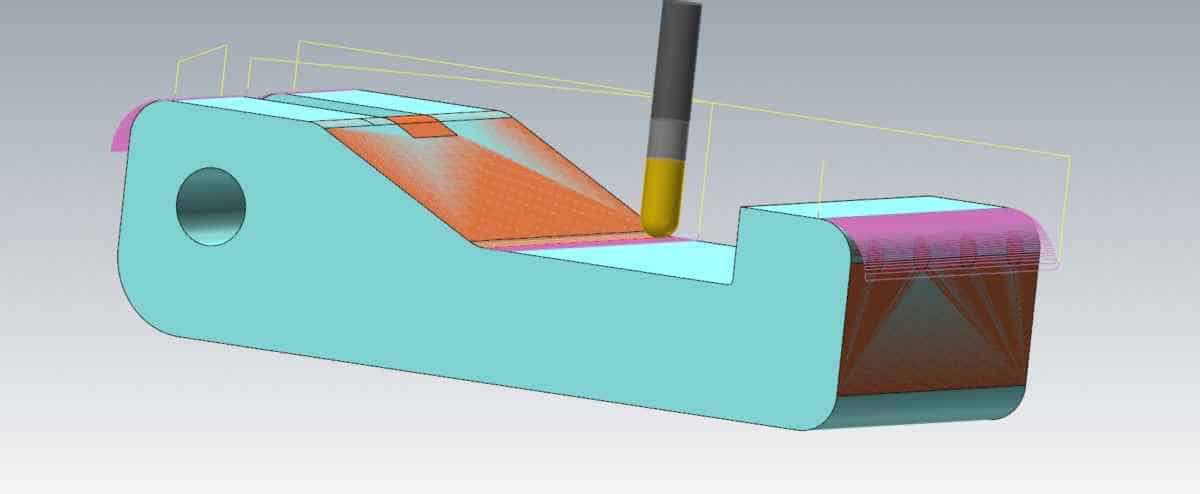

The Mastercam 2018 release, which Titletown Manufacturing has been using since its beta testing stage, provides the ability to make metal parts directly off customer-supplied models or files. This powerful software upgrade excels in the 3D manufacturing world with complex surfaces and geometries.

MazaCAM is the choice for simple parts, and the ability to complete programming offline or from a PC minimizes downtime of the machines. The system’s pre-defined tool paths make programming a snap and CNC machining an efficient process.

In the business office, Titletown Manufacturing has upgraded its JobBOSS enterprise resource planning (ERP) system to version 12.1.1 with data collection. This software upgrade enables staff to track orders in real time, with the schedule module showing capacity availability.

Titletown Manufacturing’s staff can write their own reports and print part tags without re-entering data. In addition, the purchasing module issues purchase orders to vendors without the need to re-enter details such as materials, sizes and costs.

About Titletown Manufacturing

Titletown Manufacturing is the operating division of Precision Tool & Die LLC, a trusted metal fabrication shop with more than 60 years of experience in metal parts machining, producing high-quality components and providing custom CNC machining, metalworking, grinding, and custom metal fabrication solutions for a wide range of industrial customers throughout the region. The company employs 30 people at its facility at 1252 Marine Street in Green Bay, Wisconsin.

For more information on Titletown Manufacturing or to request a quote, please go to http://www.titletownmanufacturing.com/or call 920-435-9074.

View original article on software upgrades here.