Robinson designs product handling automation that maximizes throughput

Upstream process automation is increasingly under the spotlight as product handling integrators improve line efficiencies without sacrificing throughput. Robinson works with customers to implement product handling automation systems that communicate with each other and optimize operations.

Communicating status updates between upstream and downstream equipment is one of the primary challenges in product handling. This can be especially significant for lines that feature components on multiple levels of a facility or wind their way through extensive lengths of floor space.

That’s where upstream process automation and enhanced communication and control systems can really make a difference. Our ability to integrate new and existing product handling equipment supports efficient product flow, harmonizes lines, and avoids shutdowns and slowdowns.

Lane diverter, canister loader leverage upstream process automation

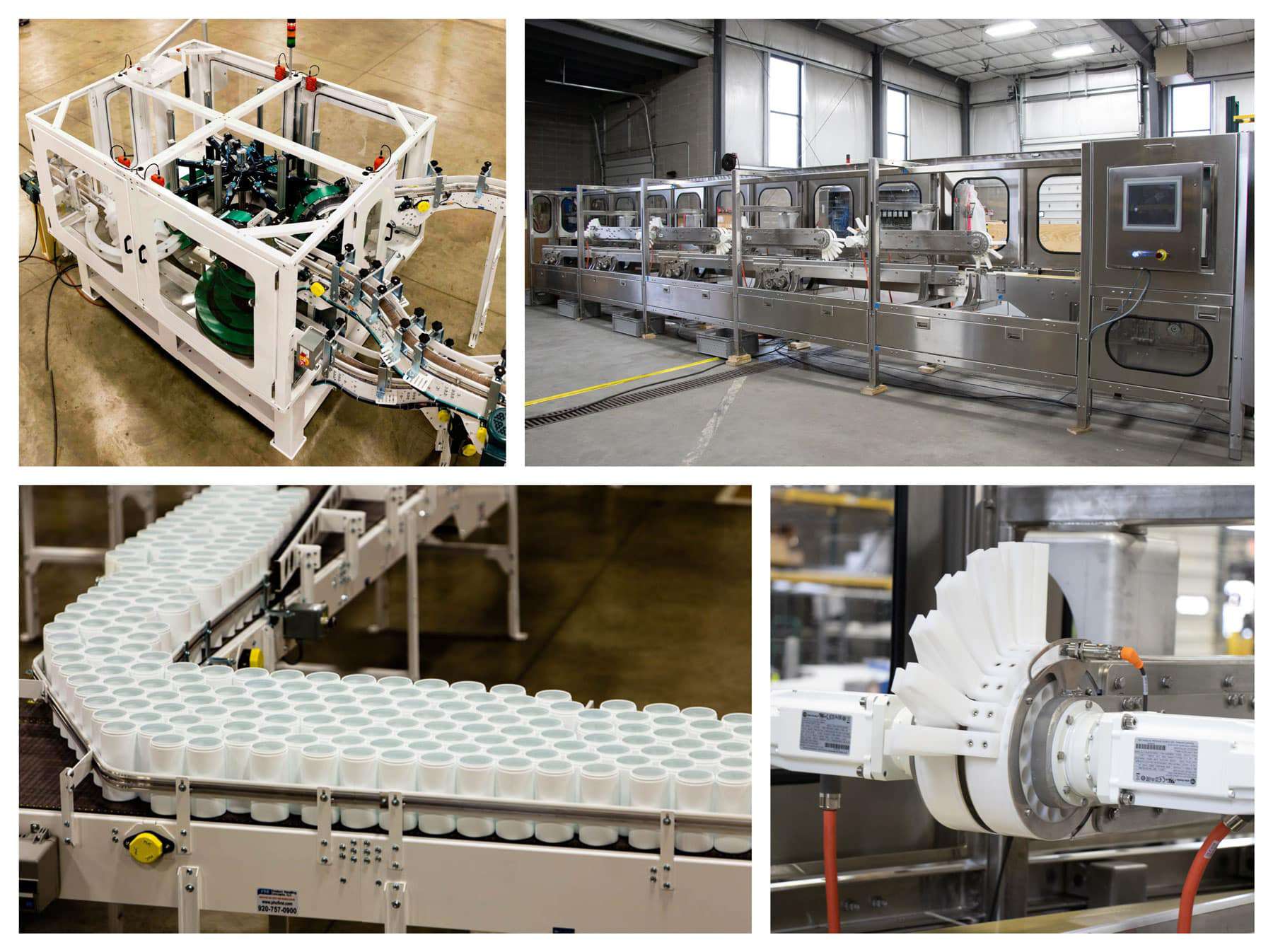

Robinson’s design teams have developed a variety of product handling automation systems that work together to boost productivity and maximize operational profits. The Servo Sweep Laner and the Momentum wipes canister loader are receiving a lot of attention for their ability to minimize accumulation issues and create a smooth flow to the case packer.

Upstream process automation is critical to the overall operation of a product line because it automatically adjusts feeds based on downstream operations. Our Servo Sweep Laner is an advanced lane diverter most commonly used for towel and tissue applications.

As an example, the Servo Sweep lane diverter manages upstream product flow in the earlier stages of production. Based on the downstream needs of the case packer, upstream process automation technology communicates with the lane diverter and other aspects of the line to create an orderly flow. This versatile technology also is effective with applications such as packaged food products, beverages, cosmetics and pharmaceutical supplies.

These types of technologies free up your workforce to perform other skilled tasks while minimizing product flow interruptions. Give us a call to learn how upstream process automation can improve operations and profitability for your organization.

About Robinson, Inc.

Robinson, Inc., is a single-source metal solutions provider based in De Pere, Wisconsin. Robinson offers manufacturing and design expertise in fabrication and machine; pipe and vessel; custom enclosures; product handling; and portable fuel solutions. The company employs more than 500 people at three locations comprising 500,000 square feet of manufacturing space.

For more information about Robinson’s capabilities or to request a quote, please call (920) 494-7411, or visit https://www.robinsoninc.com.